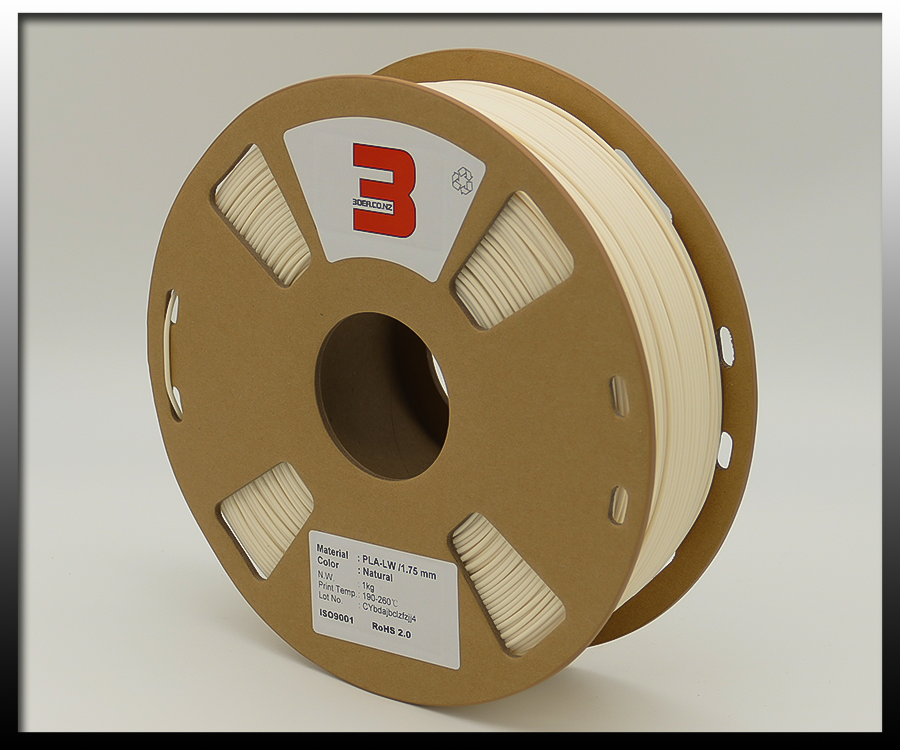

3DEA PLA-LW Natural 1.75mm Foaming Filament

$54.90

PLA-LW is primarily used for lightweight components and is widely applied in DIY model aircraft, drones, and cosplay props due to its low density and foaming properties.

1kg - Natural/Off-White

In stock

PLA-LW is primarily used for lightweight components and is widely applied in DIY model aircraft, drones, and cosplay props due to its low density and foaming properties.

3DEA PLA-LW

Diameter 1.75mm2 ±0.03

Print Temp 190-260ºC (please read description)

Hot bed 45-60ºC (optional)

Surface: Masking paper, PVP solid glue, glass board, carbon fibre board, PEI

Product features:

- Low density, up to 0.54g/cm3

- The foaming volume ratio is 220%, and 1 roll of 3DEA PLA-LW is equivalent to 2.2 rolls of ordinary PLA

- Free adjustment of strength and foaming ratio

- The excellent surface effect, matte and delicate

- Good adhesion between layers, resistance to explosion and easy to repair

- Easy to paint, strong surface paint adhesion

- Excellent printability, large models do not warp, do not block, and do not need a constant temperature chamber

Product parameters:

Physical performance indicators of unfoamed consumables:

3D PRINTING FILAMENT | Test Method | PLA-LW |

Melt Flow Index(g/10min) | GB/T 3682-2000 | 8.1(190℃/2.16kg) |

Density | GB/T 1033-86 | 1.2g/cm3 |

IZOD Impact Strength(kJ/㎡) | GB/T 1843-96 | 8.58kJ/㎡ |

Tensile Strength(MPa) | GB/T 1040-92 | 32.2MPa |

Elongation at Break(%) | GB/T 1040-92 | 68.9% |

Flexural Strength(MPa) | GB/T 9341-2000 | 41.31MPa |

Flexural Modulus(MPa) | GB/T 9341-2000 | 1701MPa |

Printing parameters

Filament | PLA-LW |

Recommended printing temperature | 190-270℃ |

Unfoamed printing temperature | 190℃ |

Foam printing temperature | 200-260℃ |

Maximum foaming temperature | 260℃ |

Maximum foaming rate (260℃) | 122% |

Lowest extrusion rate (270℃) | 45% |

Bed temperature | 45-60°C/No heating (Masking paper, PVP solid glue, glass board, carbon fibre board, PEI) |

Printing speed | 30-60mm/s |

Note: Printing test conditions: nozzle 190-280℃; layer height 0.2mm; bed 45℃; speed 40mm/s

With different temperature foaming ratio:

Temperature/℃ | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 |

Foaming rate/% | 0 | 0 | 11 | 33 | 82 | 100 | 122 | 122 | 82 |

Volume ratio/% | 100 | 100 | 111 | 133 | 182 | 200 | 222 | 222 | 182 |

Extrusion rate/% | 100 | 100 | 90 | 75 | 55 | 50 | 45 | 45 | 55 |

Density/g/cm3 | 1.2 | 1.2 | 1.08 | 0.9 | 0.66 | 0.6 | 0.54 | 0.54 | 0.66 |

speed | 40mm/s | ||||||||

Note: Print test conditions: bottom plate 45℃; speed 40mm/s

Precautions:

1. Note that the first layer speed setting is consistent with the actual printing speed, set to 100% of the actual printing speed, turn off the first layer and small area printing speed reduction function, the first layer extrusion rate is consistent with the actual foaming extrusion rate, such as 270 degrees set to 45% of the first layer extrusion rate; if the bed adhesion is too strong, you can set the bottom valve when printing.

2. Pay attention to the maximum operating temperature of the printer. Most Teflon tube printers cannot be operated for a long time above 250℃. Long-term printing above this temperature may cause blocking. If the temperature exceeds 250℃, high-temperature printers such as metal hoses are required for printing.

3. Yellowing of printed parts after high-temperature foaming is a normal phenomenon. Lowering the printing temperature can relieve it.

4. Since the PLA-LW foams continuously in the melting cavity of the high-temperature nozzle, the retraction basically does not work. Stringing is normal during printing. It is recommended to print the rc plane in vase mode to reduce the effect of stringing.

5. Foaming ratio is related to temperature, printing speed, nozzle melting cavity size, pay attention to compare model design wall thickness according to your own printing situation, adjust extrusion rate, temperature, speed and other parameters.

| Weight | 1 kg |

|---|---|

| Dimensions | 210 × 210 × 50 cm |

| Brand | |

| Colour | Natural/Off-White |

Related products

- Quick View

- Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page Details

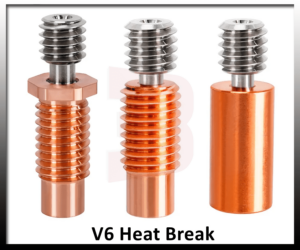

Bi-metal (titanium/copper) heat break for E3D V6 Hotends – To upgrade to a high temperature print head: up to 450-500℃

- Quick ViewAdd to cart DetailsBuy Now

3DEA Eco Pro PLA+ Filament comes on a vacuum packed cardboard reel which makes this an eco friendly option. Engineered for better printing performance.

- Quick View

Reviews

There are no reviews yet.